Make a Fold-Out Coffee Table Bed

If space trades as a high commodity in your home, clever multi-purpose furniture is always a winner. Finding the right plans that will conquer the purpose of the build can be challenging. The key to a great multifunctional piece is the perfect balance between style and functionality. This month’s project from Vermont Sales’ brand Kreg brings you just that; a strong, beautiful and dual functional fold-out coffee table bed.

Materials Required:

Wood Products:

- 2 x 3/4″ Thick, Full Sheet, MDF

- 1 x 1/4″ Thick, Quarter Sheet, MDF

- 1 x 1/2″ Thick, Quarter Sheet, MDF

- 1 x (1×3), 96″, Board

- 1 x (1×3), 48″, Board

- 8 x 3/4″ square dowel, 48″, dowel

Hardware Supplies:

- 50 x 1/14″ pocket hole screws

- 16 x 3″, #8 wood screws

- 500 x 1″, 23 gauge brads

Step 1: Cut Top and Bottom

Cut two, 45″ x 45″ squares from 3/4″ thick plywood or MDF

Step 2: Cut Sides and Faces

Step 2: Cut Sides and Faces

Cut two, 8-1/4″ x 42-1/2″ face panels and four, 8-1/4″ x 41″ sides panel from 3/4″ thick plywood or MDF. Cut the remaining scrap into 8-1/4″ lengths of material and various, random widths.

Step 3: Cut Veneer Pieces

Step 3: Cut Veneer Pieces

Cut an entire 2′ x 4′ x 1/4″ plywood or MDF “hobby panel” AND an entire 2′ x 4′ x 1/2″ plywood or MDF “hobby panel” into 8-1/4″ lengths, at random widths.

Step 4: Lower Box Face

Step 4: Lower Box Face

Align the lower box face on the top of the bottom panel. Allow a 1-1/4″ set-back from all edges. Secure in place using glue and 1-1/4″ screws through pocket holes.

Step 5: Lower Box Sides

Step 5: Lower Box Sides

Align the lower sides flush to the ends of the lower face. Allow a 1-1/4″ set-back from both sides. Secure in place using glue and 1-1/4″ screws through pocket holes.

Step 6: Upper Box Face

Step 6: Upper Box Face

Align the upper face on the underside of the Top. Allow a 1-1/4″ set-back from all edges. Secure in place using glue and 1-1/4″ screws through pocket holes.

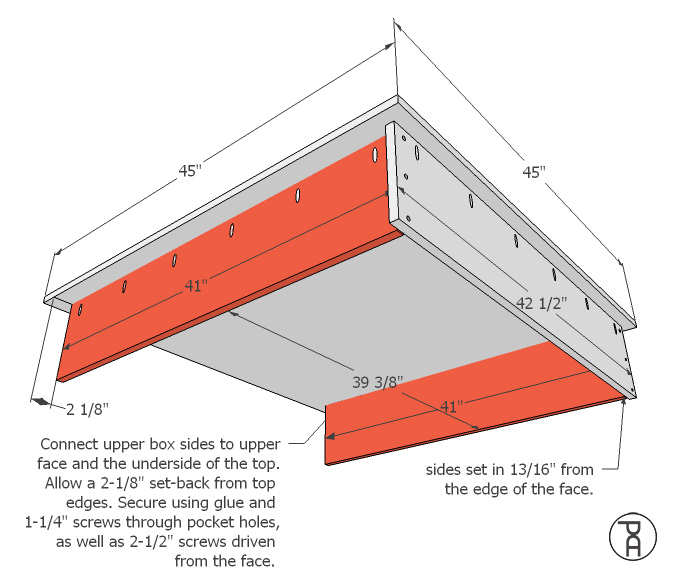

Step 7: Upper Box Sides

Step 7: Upper Box Sides

Connect the upper box sides to the upper face and the underside of the top. Allow a 2-1/8″ set-back from top edges. Secure in place using glue and 1-1/4″ screws through pocket holes, as well as 2-1/2″ screws driven from the face. The sides will be set in 13/16″ from the ends of the face board.

Step 8: Build Legs

Step 8: Build Legs

Laminate (glue together) three, 1 x 3 boards, face-to-face. Once dry, cut into five, 8-1/4″ lengths. It is much easier to glue and clamp full-length boards together and allow to dry before cutting into shorter lengths.

Step 9: Connect Legs

Step 9: Connect Legs

Drill 3/4″ pocket holes on the underside of 8, 3/4″ x 3/4 x 39″ dowels. Connect pairs of legs together, using the dowels as double, side-by-side stretchers. Create a 1/2″ space between stretchers. Align the bottom face of stretchers 3″ from the bottom of each leg. Secure in place using glue and 1-1/4″ screws.

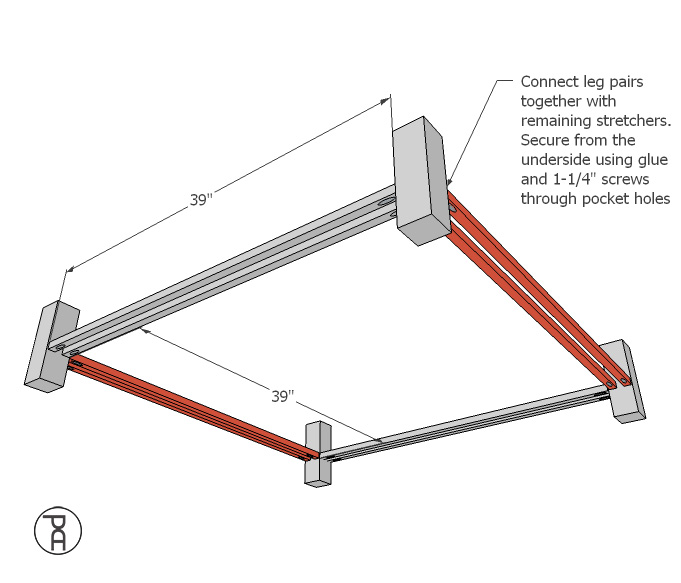

Step 10: Stretchers

Step 10: Stretchers

Connect leg pairs together with remaining stretchers. Secure in place from the underside using glue and 1-1/4″ screws through 3/4″ pocket holes.

Step 11: Attach Base

Step 11: Attach Base

Align the table base (legs and stretchers) on the underside of the lower box. Space all 4 legs 1/2″ from outer edges. Pre-drill into the top of the legs and attach using 3″ screws driven from the inside of the box.

Step 12: Center Leg

Step 12: Center Leg

Align the centre leg 8″ from the open side of the lower box panel. Pre-drill into the top of the leg and secure using two, 3″ screws.

Step 13: Add Veneer Pieces

Step 13: Add Veneer Pieces

Place the upper portion of the box on top of the lower box. Attach random-width, 8-1/4″ long veneer pieces to the lower face, sides, and upper face. Alternate the pattern of widths and thicknesses to create a random look. Secure in place using glue and 1″, 23 gauge brads.

Step 14: Finish and Add Mattress

Sand the entire surface with 220-grit sandpaper. Remove dust and paint or finish however you’d like. We recommend using an all-foam mattress. The inside of the box will accommodate a twin-XL mattress, folded in half.

Find a monthly DIY from our friends at Vermont Sales in our Digital Publications.

Find a monthly DIY from our friends at Vermont Sales in our Digital Publications.