Listen to this article in Zulu

Listen to this article in Zulu

The various components of a modular home are constructed in a controlled environment before being shipped to the location where they are assembled. This method has several benefits, including faster construction and better quality control.

In the Computer Numerical Control (CNC) machining process, production equipment and tools are moved according to pre-programmed computer software. The procedure can be used to operate a variety of complicated machinery, including mills, CNC routers, lathes, and grinders. Three-dimensional cutting jobs can be completed with CNC machining in a single set of instructions.

So, why would CNC be so beneficial to the building of modular or kit homes?

If you’ve ever experienced the highs and lows of building a home, you’ll know exactly how the climate, human error and supply chain difficulties can create chaos on a site. Modular homes built in a factory where the construction process can be monitored by experts and with no outside influence. When a modular home factory uses CNC technology, the level of precision and efficiency is increased. Human error is all but excluded.

When using CNC, no design is too complex and no level of customisation is too difficult. When the design is programmed and applied to the materials, there is no risk of getting dimensions or specifications wrong. Furthermore, the CNC machine can be fed the exact needs of the customer, down to plug ports, plumbing, and even security systems.

This just means that, once the home is assembled in the factory, it’s merely a matter of fitting everything together like Lego once on the building site.

It also leads to the customer being able to dictate all the design elements, down to the smallest detail. This way your modular home will not look like the cookie-cutter kit homes of the past – no two designs need be the same.

Traditional methods don’t apply to CNC construction – which means that materials traditionally difficult to work with by human hands are now free to use. CNC machines are able to work with any material that fulfills the rigidity specifications, which means that fully recycled materials are viable for building.

Furthermore, since the CNC milling machine calculates the exact dimensions needed from a material, there is no waste. Less material is used, less material is wasted, and this saves not only your pocket but is also great news for mother earth.

Integrating eco-building techniques and eco inclusions like a grey water system and fully integrated solar panels is as easy as clicking and waiting for the CNC machine to do its thing.

Taking all the above into consideration, it’s clear that a modular home is the most economic and eco-friendly way to build. It saves on time, materials, and labour and improves the impact that building a home has on the environment. The demand for inexpensive and reliable housing solutions is ever-increasing in today’s economic conditions.

South Africa really has some wonderful kit home / modular home manufacturers to choose from. Their designs are comprehensive enough that you will be hard-pressed to look for anything to improve or customise.

“Blockhouse modular homes are built at our factory and delivered to the site for installation in a day. Our units are designed for maximum comfort and aesthetic appeal for modern living, they have a low impact on the environment in which they are placed and have been approved by various nature and eco developments.”

Their comprehensive portfolio includes full homes, smaller guest cottage designs, and even office spaces.

Blockhouse Completed Projects

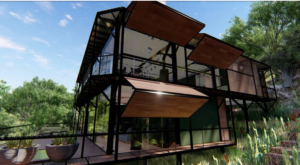

Feast your eyes on this private home in the Western Cape that Blockhouse completed. It’s modern and refined while simultaneously suiting its environment perfectly.

How cosy does this holiday rental in Dullstroom look?

Contact them today to fulfill your modular dreams

SHOWROOM

+27 12 752 8840

info@blockhouse.co.za

ONLINE

+27 66 116 3044

orders@blockhouse.co.za

Error, group does not exist! Check your syntax! (ID: 20)

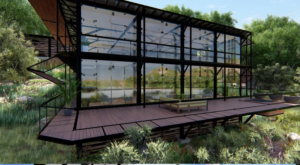

“HouseZero is an innovative building system for premium off-grid modular homes. The core guidelines and design principles of our modular houses always emphasise sleek and modern design, high-end finishes, net zero impact on the environment, integral fit of all components, and modularity.”

Just check out two of their units, the Toucan and the Eagle. There are so many jaw-dropping designs that you really should just check them out yourself.

This development in the Elephant Rock Eco Estate looks like heaven in the bushveld.

How about living your eco dream in Brooklyn, Pretoria?

Contact House Zero to access their fantastic designs today:

+27 12 006 5095

Unfortunately, South Africa doesn’t have dedicated CNC modular or kit home manufacturers, but we do have a glut of CNC suppliers.

Maybe the gap in the market is yours to fill?

We will get back to you shortly!

Error: Contact form not found.